AUSTRIA 1 Oct. 2021 – The hydrogen bus that Belgian bus maker Van Hool just delivered to Brussels-based STIB-MIVB, the city’s public transport company, is powered by onboard fueling system and cylinders designed and manufactured by Worthington Industries. This is just the latest development in a long-standing co-innovation partnership between Van Hool and Worthington to create next generation onboard fueling systems for city buses.

STIB-MIVB plans to put the 12-meter-long, hybrid (fuel cell and battery) vehicle through two years of road tests to prove the reliability of the H2 technology, its efficiency, range and maintenance costs – as well as overall operational costs, including cost reductions that are related to CO2 emissions reductions. With a max tank capacity of 39 kg of hydrogen, this A330 model bus will be able to carry out a full day’s schedule covering some 400 km.

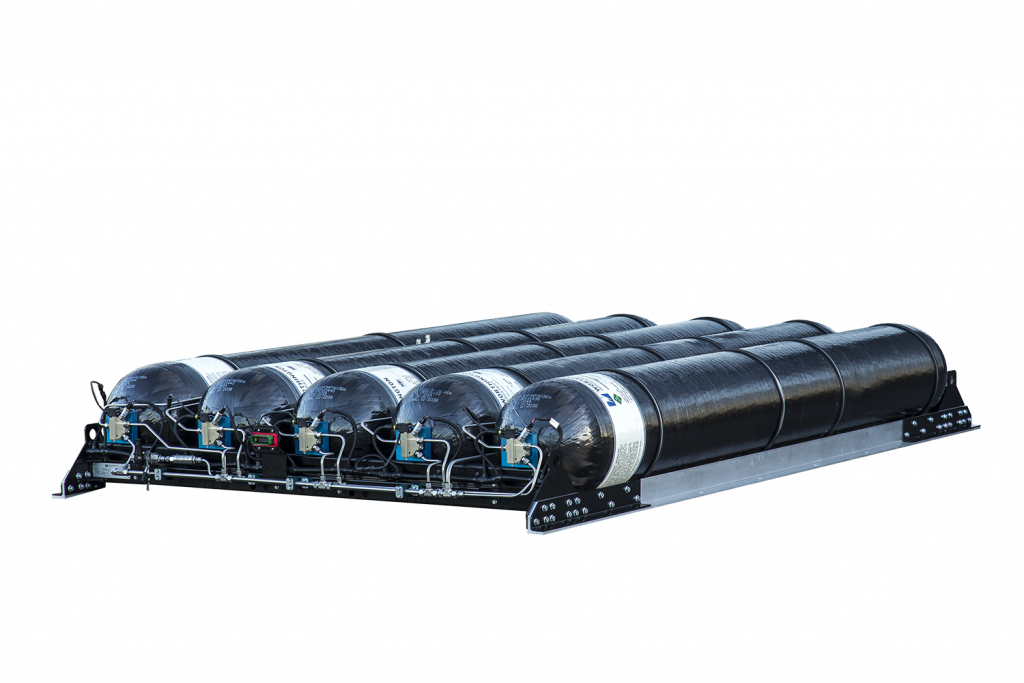

The onboard fueling system Worthington delivered to Van Hool consists of five aluminum, carbon-fiber-wrapped (Type 3) cylinders, as well as piping, gas-street components and valves, all mounted on a 100 percent aluminum frame, according to Radiša Nunić, Director European Sales and Public Affairs – Alternative Fuels I HDV of Sustainable Energy Solutions, a Europe-based business segment of Worthington Industries, whose corporate headquarters are in Columbus, Ohio. The segment has already outfitted multiple buses for Van Hool that are in service across Europe.

Van Hool, a 74-year-old, independent manufacturer of buses, coaches and industrial vehicles based in Brussels, introduced the first hydrogen bus in North America in 2005 and launched them in Europe two years later. The firm is convinced that hydrogen is an efficient and eco-friendly fuel for public transport. At present, some 162 Van Hool hydrogen buses are in operation on two continents.

“We now have Van Hool hydrogen buses operating in almost every country in Western Europe and North America,” notes CEO Filip Van Hool, “and the interest in hydrogen zero emission public transport rises exponentially in our neighboring countries. Here at Van Hool, we are making every effort to work closely with STIB-MIVB on this comprehensive and detailed research project.”

Worthington has also developed a new on-board fueling system that delivers significant weight savings of 95 kg to the finished onboard fueling system. This is made possible through Worthington’s new roof mounting frame design. “For this specific system we are using the same size of cylinders (Type 3 320 L 350 BAR), but have eliminated all steel elements in the rack,” explained Olaf Godlewski, Deputy Sales Director – Alternative Fuels Heavy Duty Vehicles, Sustainable Energy Solutions, and Van Hool Key Account Manager. “The frame now consists entirely of aluminum.”

Worthington Industries Europe Company Description

Europe is home to Worthington Industries’ Sustainable Energy Solutions business, which is dedicated to offering on-board fueling systems and services, as well as, gas containment solutions and services for the storage, transport and distribution of industrial gases supporting the growing hydrogen ecosystem and adjacent sustainable energies like compressed natural gas. Worthington incorporates sustainable practices into its long-term business strategy and is the first in its industry to bring Cradle to Cradle Certified™ products to market. The Company is the largest designer and manufacturer of pressure vessels in Europe with over 1,600 employees working at facilities in Austria, German, Poland, and Portugal. With the lightest composite and steel low- and high-pressure cylinders available, Worthington Europe designs and makes solutions for alternative fuels, industrial gases, and technical gases.

Worthington Industries (NYSE:WOR) is a leading industrial manufacturing company delivering innovative solutions to customers that span many industries including transportation, construction, industrial, agriculture, retail and energy. Worthington is North America’s premier value-added steel processor and producer of laser welded products; and a leading global supplier of pressure cylinders and accessories for applications such as fuel storage, water systems, outdoor living, tools and celebrations. The Company’s brands, primarily sold in retail stores, include Coleman®, Bernzomatic®, Balloon Time®, Mag Torch®, Well-X-Trol®, General®, Garden-Weasel®, Pactool International® and Hawkeye™. Worthington’s WAVE joint venture with Armstrong is the North American leader in innovative ceiling solutions.

Headquartered in Columbus, Ohio, Worthington operates 53 facilities in 15 states and seven countries, sells into over 90 countries and employs approximately 8,000 people. Founded in 1955, the Company follows a people-first philosophy with earning money for its shareholders as its first corporate goal. Relentlessly finding new ways to drive progress and practicing a shared commitment to transformation, Worthington makes better solutions possible for customers, employees, shareholders and communities.

Safe Harbor Statement

The Company wishes to take advantage of the Safe Harbor provisions included in the Private Securities Litigation Reform Act of 1995 (the “Act”). Statements by the Company which are not historical information constitute “forward looking statements” within the meaning of the Act. All forward-looking statements are subject to risks and uncertainties which could cause actual results to differ from those projected. Factors that could cause actual results to differ materially include risks, uncertainties and impacts described from time to time in the Company’s filings with the Securities and Exchange Commission, including those related to COVID-19 and the various actions taken in connection therewith, which could also heighten other risks.

Worthington’s onboard fueling system consists of five aluminum, carbon-fiber-wrapped (Type 3) cylinders, mounted on an aluminum frame.

Worthington also designs and makes the piping, gas-street components and valves for the system. STIB-MIVB plans TO operate the hybrid (fuel cell and battery) vehicle through two years of road tests to prove the reliability of the H2 technology, its efficiency, range and maintenance costs. Van Hool’s bus has a max tank capacity of 39 kg of hydrogen – enough to cover a full bus of some 400 km.